Fuel Filter Costs: Finding Affordable Options

Optimizing Fuel Filter Expenditures: Strategies for Cost-Conscious Procurement

Understanding Fuel Filter Costs

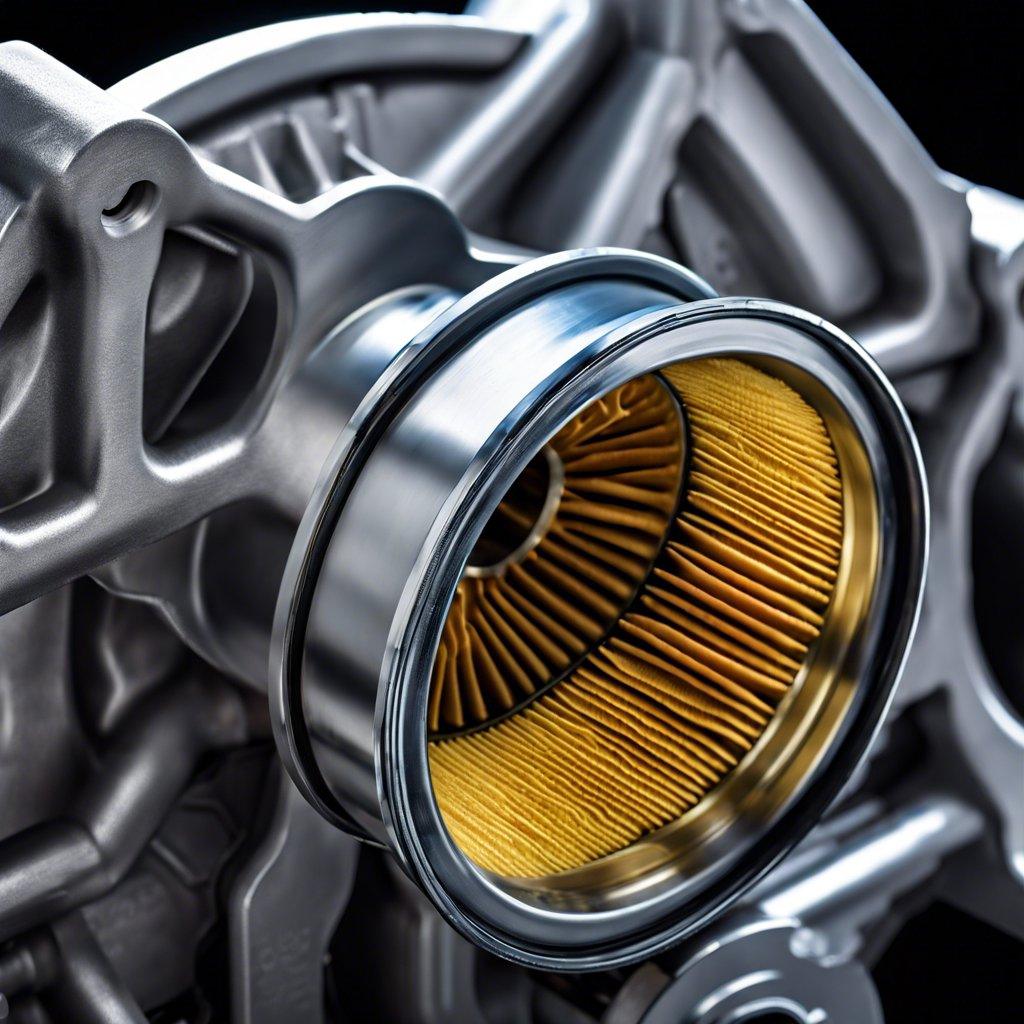

Fuel filters play a crucial role in maintaining the efficiency and longevity of your vehicle’s engine. However, the cost of these essential components can quickly add up, especially for fleet managers or individuals with multiple vehicles. Identifying affordable options and implementing cost-saving strategies is key to optimizing fuel filter expenditures.

Factors Influencing Fuel Filter Prices

Fuel filter prices can vary depending on several factors, including the type of filter, the vehicle’s make and model, and the brand. Original equipment manufacturer (OEM) filters are typically more expensive than aftermarket options, but they may offer superior quality and performance. Understanding these cost drivers can help you make informed purchasing decisions.

Strategies for Cost-Conscious Procurement

To ensure that you are getting the most value for your money, consider the following strategies:

- Explore aftermarket fuel filter options that meet or exceed OEM specifications at a lower cost.

- Leverage bulk purchasing opportunities to take advantage of volume discounts, particularly if you have a fleet of vehicles.

- Regularly monitor market prices and compare offers from multiple suppliers to find the best deals.

- Implement a proactive maintenance schedule to replace fuel filters at the recommended intervals, preventing costly engine repairs down the line.

Comparing Fuel Filter Costs

| Filter Type | Average Price Range | Estimated Annual Savings* |

|---|---|---|

| OEM Fuel Filter | $50 – $100 | N/A |

| Aftermarket Fuel Filter | $20 – $50 | $30 – $50 per filter |

*Estimated annual savings based on replacing fuel filters every 12,000 miles.

Optimizing fuel filter expenditures requires a balanced approach. By understanding the factors that influence filter costs and implementing cost-conscious procurement strategies, engineering and technology employees can ensure that their organizations are getting the most value for their money while maintaining the integrity of their vehicle’s fuel systems.

Maximizing Fuel Filter Value: Balancing Quality and Cost

As engineering and technology professionals, managing fuel filter expenses is a critical aspect of maintaining efficient and cost-effective operations. In this comprehensive guide, we’ll explore the landscape of economical fuel filter solutions, empowering you to make informed decisions that align with your budgetary requirements without compromising quality.

Understanding Fuel Filter Pricing Factors

The cost of fuel filters can vary significantly, depending on factors such as brand, materials, and filtration capacity. By understanding these key elements, you can identify opportunities to optimize your fuel filter budget while ensuring optimal engine performance.

Exploring Affordable Fuel Filter Options

To navigate the landscape of economical fuel filter solutions, consider the following strategies:

- Aftermarket Fuel Filters: Investigate the availability and quality of aftermarket fuel filters, which can often provide substantial cost savings compared to original equipment manufacturer (OEM) options.

- Bulk Purchasing: Look into the potential for volume discounts when purchasing fuel filters in bulk, particularly if you manage a fleet or have multiple vehicles that require regular filter replacements.

- Remanufactured Fuel Filters: Explore the option of remanufactured fuel filters, which can offer significant cost savings while maintaining performance standards.

Balancing Quality and Cost

While cost is an essential factor, it’s crucial to ensure that the fuel filters you choose meet the necessary quality standards to protect your engine and maintain optimal performance. Consider the following factors when evaluating fuel filter options:

- Filtration Efficiency: Ensure that the fuel filters you select effectively remove contaminants, preventing potential engine damage.

- Flow Rate: Verify that the fuel filter’s flow rate matches the requirements of your engine, ensuring uninterrupted fuel delivery.

- Durability: Opt for fuel filters with a proven track record of reliability and longevity to minimize the need for frequent replacements.

Fuel Filter Replacement Strategies

To further optimize your fuel filter budget, consider the following strategies for replacement:

| Strategy | Potential Cost Savings |

|---|---|

| Proactive Replacement | Replacing fuel filters at the recommended intervals can prevent costly engine repairs and downtime. |

| Preventive Maintenance | Regularly inspecting and servicing fuel filters can extend their useful life, reducing replacement frequency. |

| DIY Fuel Filter Changes | Performing fuel filter changes yourself, when feasible, can eliminate labor costs associated with professional servicing. |

By understanding the factors that influence fuel filter costs and exploring a range of economical solutions, you can effectively manage your fuel filter budget while maintaining the integrity and performance of your engines. Embrace a proactive approach to fuel filter maintenance and replacement to optimize your operations and maximize cost savings.

Fuel Filter Savings: Unlocking the Power of Strategic Sourcing

Maximizing Fuel Filter Cost Efficiency

As engineering and technology employees, we understand the importance of maintaining optimal equipment performance and minimizing operational costs. One crucial aspect of this is the selection and procurement of fuel filters, which play a vital role in ensuring the longevity and efficiency of our machinery. In this comprehensive guide, we will explore strategies for unlocking the power of strategic sourcing to achieve significant fuel filter savings.

Evaluating Fuel Filter Options

The fuel filter market offers a wide range of options, each with its own set of features, quality, and price points. It’s essential to carefully evaluate the available choices to identify the most cost-effective solutions that meet your specific requirements. Consider factors such as:

- Filter performance and efficiency

- Compatibility with your equipment

- Durability and lifespan

- Warranty and after-sales support

Strategic Sourcing Techniques

Leveraging strategic sourcing techniques can be a game-changer in your quest for fuel filter cost savings. Explore the following approaches:

- Bulk purchasing: Negotiate better prices by ordering fuel filters in larger quantities

- Vendor partnerships: Develop long-term relationships with reliable suppliers to secure preferential pricing and terms

- Competitive bidding: Invite multiple vendors to submit proposals and compare offers to find the most competitive solutions

- Inventory optimization: Implement effective inventory management strategies to minimize waste and ensure timely availability of fuel filters

Cost Comparison and Analysis

Conduct a thorough cost comparison and analysis to identify the most cost-effective fuel filter options. Utilize the power of data-driven decision-making by compiling and analyzing the following information:

| Vendor | Product | Unit Price | Quantity Discount | Shipping Costs | Total Cost |

|---|---|---|---|---|---|

| Vendor A | Filter XYZ | $10.00 | 5% for orders over 50 units | $2.00 per order | $540.00 |

| Vendor B | Filter ABC | $8.50 | 10% for orders over 100 units | Free shipping | $765.00 |

Ongoing Optimization and Monitoring

Maintaining a vigilant approach to fuel filter procurement is crucial. Continuously monitor market trends, supplier performance, and technological advancements to ensure that you’re always leveraging the most cost-effective and efficient solutions. Regularly review your fuel filter sourcing strategy and make adjustments as needed to maximize your savings.

Fuel Filter Expenditure Management: Balancing Quality and Cost-Effectiveness

Optimizing Fuel Filter Expenditure

Fuel filters play a crucial role in maintaining the efficiency and longevity of vehicle engines. However, the cost of replacing these essential components can quickly add up, creating a significant financial burden for engineering and technology employees. This article explores strategies for managing fuel filter expenditure while ensuring quality and cost-effectiveness.

Understanding Fuel Filter Importance

Fuel filters are designed to remove impurities and contaminants from the fuel, preventing them from reaching the engine and causing damage. Neglecting regular fuel filter replacement can lead to decreased fuel efficiency, increased emissions, and even engine failure. Maintaining a proactive approach to fuel filter management is essential for maximizing the performance and lifespan of vehicle engines.

When it comes to fuel filters, there is a wide range of options available, each with its own set of features and price points. Factors to consider include filter material, filtration efficiency, and compatibility with your vehicle’s make and model. While premium fuel filters may carry a higher initial cost, they often provide superior filtration and longer service life, ultimately delivering better value in the long run.

Budgeting and Cost-Saving Strategies

Effective fuel filter expenditure management requires a strategic approach to budgeting and cost-saving initiatives. Some key strategies include:

- Researching and comparing prices from multiple vendors to find the most competitive deals

- Leveraging bulk purchasing or fleet discounts, if available

- Considering the long-term cost of ownership by factoring in filter lifespan and replacement intervals

- Implementing a preventive maintenance schedule to avoid unexpected fuel filter failures and costly repairs

Balancing Quality and Cost-Effectiveness

The ultimate goal is to strike a balance between quality and cost-effectiveness when managing fuel filter expenditure. This may involve investing in premium filters that offer superior performance and longevity, or exploring alternative options that provide a favorable balance of quality and affordability. By adopting a strategic and data-driven approach, engineering and technology employees can optimize their fuel filter expenditure while maintaining the integrity of their vehicle’s fuel system.

| Filter Type | Filtration Efficiency | Estimated Lifespan | Average Cost |

|---|---|---|---|

| Standard Fuel Filter | Moderate | 12-18 months | $10-$30 |

| Premium Fuel Filter | High | 18-24 months | $20-$50 |

| Synthetic Fuel Filter | Very High | 24-36 months | $30-$80 |

By carefully evaluating fuel filter options, implementing cost-saving strategies, and balancing quality and cost-effectiveness, engineering and technology employees can optimize their fuel filter expenditure and ensure the long-term performance and reliability of their vehicle’s fuel system.

Post Comment