Preventive Maintenance: The Importance of Regular Fuel Filter Changes

Safeguarding Engine Efficiency: The Pivotal Role of Fuel Filter Maintenance

The Importance of Fuel Filter Maintenance

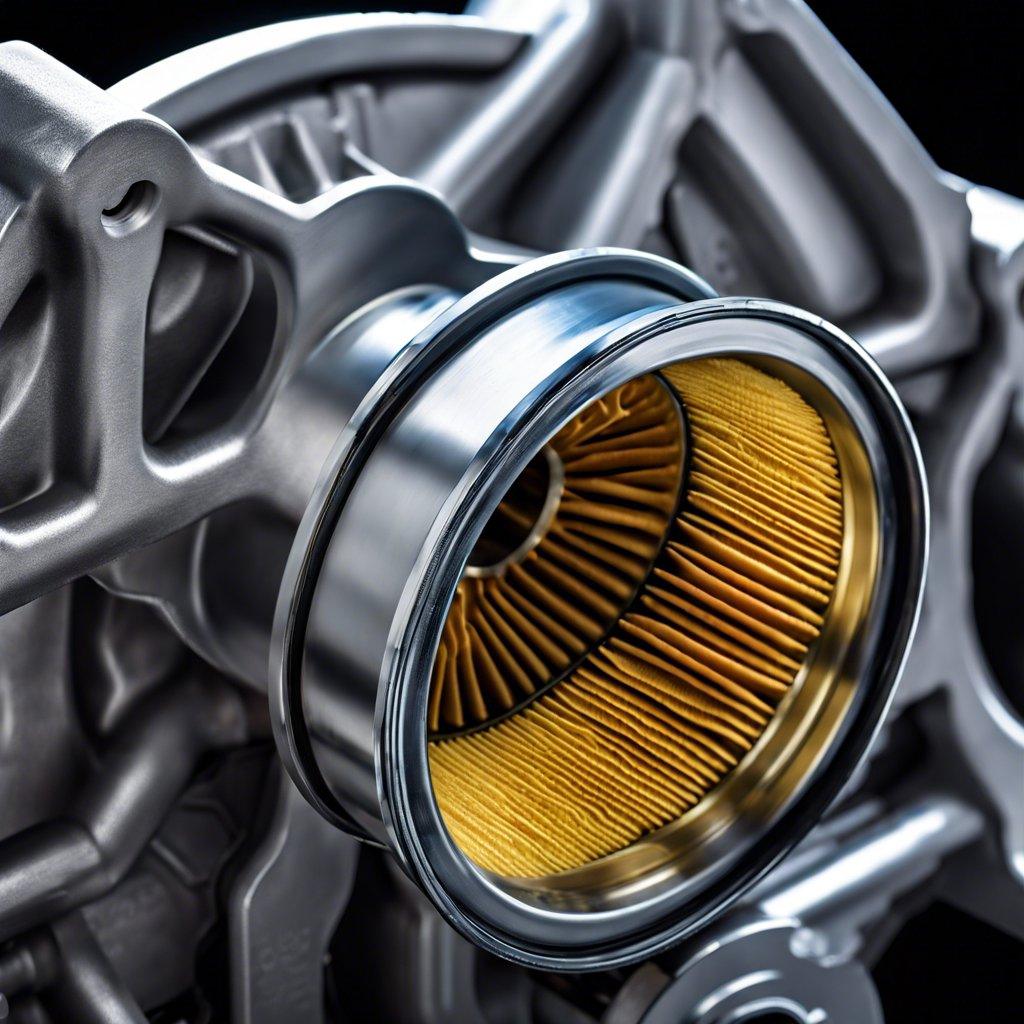

Fuel filters play a crucial role in ensuring the optimal performance and longevity of your engine. Regular fuel filter changes are essential for maintaining engine efficiency, preventing costly repairs, and ensuring the reliable operation of your equipment.

Understanding the Function of Fuel Filters

Fuel filters are designed to remove impurities, contaminants, and debris from the fuel before it reaches the engine. Over time, these filters can become clogged, restricting the flow of fuel and reducing the engine’s performance. Neglecting to change the fuel filter can lead to a range of issues, including decreased fuel efficiency, reduced power, and even engine failure.

The Consequences of Neglecting Fuel Filter Maintenance

Failing to change the fuel filter at the recommended intervals can have severe consequences for your engine’s performance and longevity. Some of the key issues that can arise include:

- Reduced Fuel Efficiency: A clogged fuel filter restricts the flow of fuel, forcing the engine to work harder to maintain the same level of power. This can result in a significant decrease in fuel efficiency, leading to higher operating costs.

- Decreased Engine Power: As the fuel filter becomes more restricted, the engine’s ability to deliver power is diminished, resulting in a noticeable loss of performance.

- Increased Risk of Engine Failure: A severely clogged fuel filter can cause the engine to stall or even lead to complete engine failure, resulting in costly repairs and downtime.

Establishing a Preventive Maintenance Routine

To ensure the optimal performance and longevity of your engine, it is essential to establish a preventive maintenance routine that includes regular fuel filter changes. The recommended frequency for fuel filter replacement can vary depending on the manufacturer’s specifications, the operating environment, and the type of fuel used. As a general guideline, it is recommended to change the fuel filter every 12,000 to 24,000 miles or every 12 to 24 months, whichever comes first.

The Benefits of Proactive Fuel Filter Maintenance

By prioritizing fuel filter maintenance, you can enjoy a range of benefits that will contribute to the overall efficiency and reliability of your equipment:

- Improved Fuel Efficiency: A clean fuel filter ensures that fuel is delivered to the engine without restriction, improving overall fuel efficiency and reducing operating costs.

- Enhanced Engine Performance: Properly functioning fuel filters allow the engine to operate at its optimal level, delivering consistent power and responsiveness.

- Extended Engine Lifespan: Preventing fuel system issues through regular filter changes can help extend the overall lifespan of your engine, reducing the need for costly repairs or replacements.

- Reduced Maintenance Costs: Proactive fuel filter maintenance can help you avoid the higher costs associated with repairing or replacing engine components damaged by contaminants or fuel system issues.

Fuel filter maintenance is a critical component of preventive maintenance for your engine. By prioritizing regular fuel filter changes, you can safeguard the efficiency, performance, and longevity of your equipment, ultimately contributing to the overall reliability and cost-effectiveness of your operations.

Unleash Peak Performance: Optimizing Fuel Flow through Periodic Filter Replacements

Fuel Filtration: The Unsung Hero of Engine Efficiency

In the world of engineering and technology, where performance and reliability are paramount, one often-overlooked component plays a crucial role – the humble fuel filter. This unsung hero of engine efficiency is the gatekeeper, ensuring that only clean, contaminant-free fuel reaches the critical components of your machinery, unleashing its full potential.

The Perils of Clogged Fuel Filters

As fuel travels from the tank to the engine, it can pick up a myriad of impurities, from dirt and debris to water and even microbial growth. These contaminants can wreak havoc on your engine’s delicate fuel system, leading to reduced power, decreased fuel efficiency, and in extreme cases, costly breakdowns.

A clogged fuel filter restricts the flow of fuel, causing the engine to struggle to perform at its best, compromising the overall efficiency and performance of your equipment.

Periodic Filter Replacements: A Small Investment with Big Rewards

The solution to this challenge lies in the routine replacement of your fuel filters. By proactively maintaining this critical component, you can ensure that your machinery is always receiving the clean, unobstructed fuel flow it needs to operate at peak efficiency.

Regular filter changes not only protect your engine from the detrimental effects of contaminants but also contribute to extended engine life, improved fuel economy, and reduced maintenance costs.

Optimize Your Maintenance Routine

To ensure optimal performance and longevity, it is recommended to replace your fuel filters at the intervals specified by the manufacturer or based on your operating conditions. Factors such as the age of your equipment, operating environment, and fuel quality can all influence the recommended replacement schedule.

Unlock the Full Potential of Your Equipment

By embracing a proactive fuel filtration maintenance strategy, you can unlock the full potential of your engineering and technology equipment. Periodic fuel filter replacements are a small investment that yield substantial dividends in the form of improved performance, enhanced efficiency, and extended equipment lifespan.

- Protect your engine from contaminants

- Enhance fuel efficiency and power output

- Reduce maintenance costs and downtime

- Extend the lifespan of your critical equipment

| Fuel Filter Replacement Interval | Recommended Action |

|---|---|

| Every 12 months or 12,000 miles | Replace the fuel filter |

| If the filter appears clogged or restricted | Replace the fuel filter immediately |

Embrace the power of preventive maintenance and unlock the full potential of your engineering and technology equipment through regular fuel filter replacements.

Mitigating Downtime: How Fuel Filter Vigilance Preserves Engine Reliability

The Vital Role of Fuel Filters

In the realm of engine maintenance, the fuel filter stands as a silent guardian, playing a pivotal role in preserving the reliability and longevity of your equipment. As an engineering or technology professional, understanding the importance of regular fuel filter changes is crucial to minimizing costly downtime and ensuring optimal engine performance.

Defending Against Contaminants

The fuel system is a delicate and intricate network, with the fuel filter serving as the first line of defense against impurities and contaminants. Over time, these unwanted particles can accumulate, clogging the filter and restricting the flow of fuel. This can lead to a range of issues, from reduced engine power and efficiency to complete engine failure.

Extending Engine Lifespan

By consistently replacing your fuel filters according to the manufacturer’s recommendations, you can safeguard your engine’s critical components, such as the fuel pump and injectors, from premature wear and tear. This proactive approach not only extends the overall lifespan of your equipment but also helps to maintain its performance and fuel efficiency, ultimately reducing operational costs and downtime.

Preventing Costly Repairs

A neglected fuel filter can cause a domino effect of problems, leading to costly repairs and unplanned downtime. Clogged filters can cause the fuel system to become starved of fuel, leading to issues such as rough idling, misfiring, and even engine stalling. By prioritizing regular fuel filter changes, you can avoid these disruptive and expensive scenarios, keeping your equipment running smoothly and your operations uninterrupted.

Fuel Filter Maintenance Strategies

- Adhere to Manufacturer Recommendations: Consult your equipment’s owner’s manual and follow the recommended fuel filter change intervals to ensure optimal protection.

- Monitor Fuel System Performance: Keep a close eye on any changes in engine performance, fuel efficiency, or unusual noises, as these could be early indicators of a clogged or failing fuel filter.

- Invest in High-Quality Replacement Filters: Opt for genuine or OEM-approved fuel filters to ensure compatibility and performance standards.

Heavy-Duty Equipment250 – 500 hours of operation

| Fuel Filter Replacement Interval | Typical Mileage |

|---|---|

| Light-Duty Vehicles | 12,000 – 15,000 miles |

By prioritizing regular fuel filter changes, you can mitigate downtime, preserve engine reliability, and ensure the long-term performance and efficiency of your equipment. Investing in this essential maintenance practice will pay dividends in the form of reduced operational costs, increased productivity, and a healthier bottom line.

Extending Engine Lifespan: The Transformative Impact of Proactive Fuel Filter Care

At the heart of every modern engine lies a critical component: the fuel filter. This unassuming device plays a pivotal role in ensuring the long-term health and performance of your engine. By trapping impurities and contaminants, fuel filters safeguard the sensitive components of your engine, preventing costly damage and extending its operational lifespan.

The Hidden Dangers of Neglected Fuel Filters

Ignoring the regular replacement of your fuel filter can have detrimental consequences. As the filter becomes clogged with accumulated debris, it restricts the flow of fuel to the engine, reducing power and efficiency. This can lead to a host of issues, including decreased fuel economy, reduced engine responsiveness, and, in the worst-case scenario, complete engine failure.

Proactive Fuel Filter Maintenance: The Key to Engine Longevity

Implementing a proactive fuel filter maintenance regimen is the key to unlocking the full potential of your engine. By replacing the fuel filter at the recommended intervals, you can ensure that your engine receives a consistent, unobstructed supply of clean fuel, optimizing performance and minimizing the risk of costly repairs.

The Transformative Impact of Fuel Filter Care

Investing in regular fuel filter changes can have a profound impact on the lifespan and performance of your engine. By keeping your fuel system free of contaminants, you can:

- Improve Fuel Efficiency: A clean fuel filter allows for optimal fuel flow, resulting in improved fuel economy and reduced operating costs.

- Enhance Engine Power and Responsiveness: Unobstructed fuel delivery ensures your engine operates at peak performance, delivering the power and acceleration you demand.

- Extend Engine Lifespan: Protecting your engine’s sensitive components from abrasive contaminants can significantly extend its operational lifespan, saving you from the expense of premature engine replacement.

Conclusion: Prioritize Proactive Fuel Filter Maintenance

In the world of engineering and technology, where every component plays a crucial role, the fuel filter stands out as a silent hero. By making proactive fuel filter care a priority, you can unlock the full potential of your engine, enjoying enhanced performance, improved efficiency, and extended lifespan. Invest in the long-term health of your engine today and reap the rewards of a well-maintained fuel system.

| Recommended Fuel Filter Replacement Intervals |

|---|

| Light-Duty Vehicles: Every 12 months or 12,000 miles (20,000 km) |

| Heavy-Duty Vehicles: Every 6 months or 6,000 miles (10,000 km) |

| Severe Conditions: Every 3 months or 3,000 miles (5,000 km) |

Post Comment