The Final Word on Fuel Filters: Expert Insights and Maintenance Strategies

Unraveling the Mysteries: The Vital Role of Fuel Filters in Engine Performance

Understanding the Importance of Fuel Filters

Fuel filters play a critical role in maintaining the optimal performance and longevity of any engine. These unsung heroes of the automotive world are responsible for removing contaminants, debris, and impurities from the fuel supply, ensuring that your engine receives the clean, high-quality fuel it needs to operate efficiently.

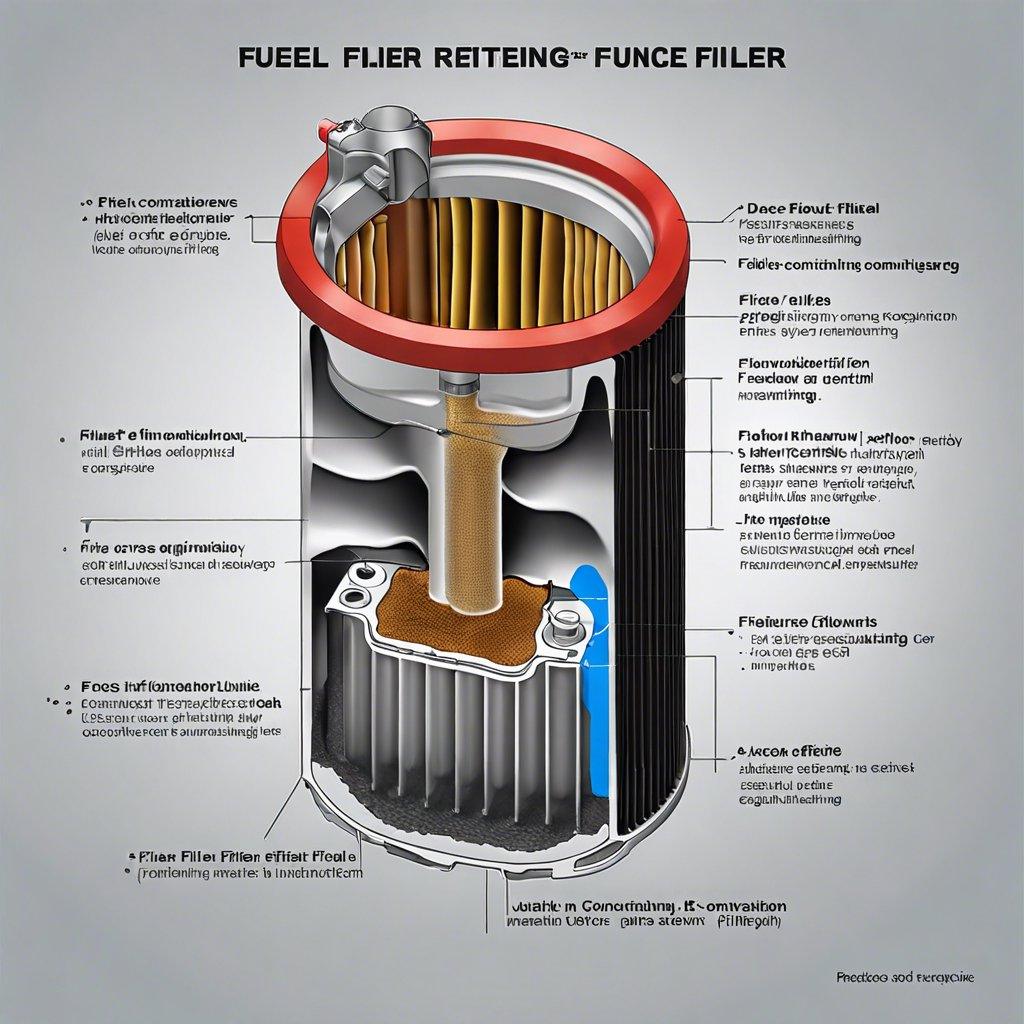

The Anatomy of a Fuel Filter

Fuel filters are typically composed of a sturdy housing, a filtration media, and a bypass valve. The filtration media, often made of pleated paper or synthetic materials, traps various particles and impurities, preventing them from reaching the fuel system’s sensitive components. The bypass valve, on the other hand, ensures that fuel can still flow in the event of a clogged filter, protecting the engine from potential damage.

The Impact of a Clogged Fuel Filter

When a fuel filter becomes clogged, the engine can experience a range of problems, including reduced fuel flow, decreased power output, and even engine stalling. In extreme cases, a severely restricted fuel filter can lead to premature wear and tear on fuel pumps, injectors, and other critical components.

Fuel Filter Maintenance and Replacement

Regular maintenance and timely replacement of fuel filters are essential to ensure optimal engine performance and prevent costly repairs. Most manufacturers recommend replacing fuel filters at specific mileage intervals, typically every 30,000 to 50,000 miles, or as specified in the vehicle’s owner’s manual.

| Maintenance Interval | Recommended Action |

|---|---|

| Every 30,000 to 50,000 miles | Replace fuel filter |

| During routine service | Inspect fuel filter for signs of wear or damage |

Choosing the Right Fuel Filter

When it comes to selecting a replacement fuel filter, it’s crucial to choose a high-quality, OEM-approved part that is compatible with your vehicle’s make, model, and engine. Investing in a quality fuel filter can help extend the life of your engine and prevent costly repairs down the line.

- Look for filters with a high filtration rating to ensure maximum protection against contaminants.

- Consider filters with advanced features, such as water-separating capabilities, for enhanced fuel system protection.

- Consult your vehicle’s owner’s manual or a trusted mechanic for the recommended fuel filter specifications.

Fuel filters are the unsung heroes of engine performance, playing a vital role in maintaining the health and efficiency of your vehicle’s fuel system. By understanding the importance of fuel filters, following recommended maintenance schedules, and choosing the right replacement parts, you can help ensure that your engine operates at its best for years to come.

Proactive Maintenance: Strategies to Maximize Fuel Filter Longevity and Efficiency

Importance of Fuel Filter Maintenance

Fuel filters play a critical role in ensuring the efficient and reliable operation of engines in various industrial and commercial applications. Proper maintenance of these filters is essential to prevent premature wear, engine damage, and downtime. This article delves into expert insights and strategies to proactively maintain fuel filters and maximize their longevity and efficiency.

Understanding Fuel Filter Functionality

Fuel filters are designed to remove contaminants, such as dirt, rust, and water, from the fuel supply before it reaches the engine. This helps to protect sensitive fuel system components, including injectors and pumps, from wear and damage. Regularly replacing fuel filters is crucial to maintain optimal engine performance and fuel efficiency.

Proactive Maintenance Strategies

To maximize the longevity and efficiency of fuel filters, consider the following proactive maintenance strategies:

- Scheduled Replacement: Adhere to the manufacturer’s recommended replacement intervals for fuel filters. This ensures that the filters are changed before they become clogged and impede fuel flow.

- Fuel Quality Monitoring: Regularly monitor the quality of the fuel being used, as contaminants in the fuel can accelerate the clogging of the filter. Consider implementing a fuel filtration system to further purify the fuel supply.

- Pre-filter Installation: Install a pre-filter upstream of the primary fuel filter to capture larger contaminants and extend the life of the primary filter.

- Proper Installation: Ensure that fuel filters are installed correctly, with the flow direction aligned correctly, to prevent leaks and ensure optimal performance.

Troubleshooting and Replacement

If you suspect that a fuel filter is clogged or failing, it is essential to diagnose the issue promptly and replace the filter if necessary. Signs of a clogged filter may include reduced fuel flow, decreased engine performance, or even engine stalling. Consult the manufacturer’s guidelines for the appropriate replacement filter and follow their installation instructions to ensure proper fit and function.

Proactive maintenance of fuel filters is crucial for maintaining the efficiency and reliability of engines in various industrial and commercial applications. By understanding the importance of fuel filter functionality, implementing strategic maintenance practices, and promptly addressing any issues, you can maximize the longevity and performance of your fuel filtration system.

Cutting-Edge Filtration Technology: Innovations that Elevate Fuel System Protection

In the ever-evolving world of automotive engineering, the critical role of fuel filters cannot be overstated. As the industry continues to push the boundaries of performance and efficiency, the demand for advanced filtration solutions has become more pressing than ever. This comprehensive guide delves into the cutting-edge innovations in fuel filtration technology, equipping engineering and technology professionals with the insights they need to safeguard the integrity of their fuel systems.

Enhancing Fuel Purity: The Cornerstone of Optimal Engine Performance

At the heart of any high-performing fuel system lies the fuel filter, a vital component responsible for removing impurities and contaminants from the fuel supply. Cutting-edge filtration technologies have revolutionized the way fuel filters operate, delivering unprecedented levels of fuel purity and system protection.

Microfiltration: The New Standard in Fuel Filtration

One of the most significant advancements in fuel filtration is the emergence of microfiltration technology. These advanced filters are engineered to capture even the smallest of particulates, including those invisible to the naked eye. By removing these microscopic contaminants, microfiltration systems ensure that only the purest fuel reaches the engine, minimizing the risk of costly breakdowns and extending the lifespan of critical fuel system components.

Adaptive Filtration: Tailoring Protection to Changing Conditions

Fuel quality and contaminant levels can fluctuate significantly based on factors such as geographic location, weather conditions, and fuel source. Adaptive filtration systems have been developed to address this challenge, automatically adjusting their performance to maintain optimal fuel purity regardless of the operating environment.

Integrated Sensor Technology: Proactive Fuel System Monitoring

Integrated sensor technology is another key innovation in fuel filtration, providing real-time monitoring of fuel quality and filter performance. By continuously tracking parameters such as pressure, flow rate, and contaminant levels, these advanced systems can alert users to potential issues before they escalate, enabling proactive maintenance and minimizing downtime.

The Future of Fuel Filtration: Embracing Sustainability and Efficiency

- Eco-friendly filter materials: Leveraging sustainable, biodegradable materials to reduce the environmental impact of fuel filtration.

- Self-cleaning filter designs: Innovative filter structures that can regenerate and extend their useful life, minimizing waste and maintenance requirements.

- Intelligent filter management: Advanced algorithms and machine learning to optimize filter replacement intervals, maximizing efficiency and cost-effectiveness.

| Key Filtration Innovation | Benefit to Fuel System |

|---|---|

| Microfiltration | Enhanced fuel purity, extended component lifespan |

| Adaptive Filtration | Optimized protection across varying operating conditions |

| Integrated Sensor Technology | Proactive maintenance, reduced downtime |

| Eco-friendly Materials | Sustainable, environmentally-conscious filtration solutions |

As the automotive industry continues to evolve, the importance of fuel filtration technology cannot be overstated. By embracing cutting-edge innovations, engineering and technology professionals can elevate the performance, reliability, and sustainability of their fuel systems, paving the way for a more efficient and environmentally-conscious future.

Fuel Filter Troubleshooting: Identifying and Resolving Common Issues for Optimal Engine Operation

Ensuring optimal engine performance is crucial for engineering and technology professionals, and the fuel filter plays a vital role in maintaining engine health. This comprehensive guide delves into the common issues associated with fuel filters and provides expert insights on how to identify and resolve them, empowering you to maintain your engine’s efficiency and longevity.

Recognizing Fuel Filter-Related Problems

Fuel filter-related issues can manifest in various ways, and it’s essential to be able to identify them promptly. Some common signs of a problematic fuel filter include:

- Decreased fuel efficiency

- Rough idling or stalling

- Reduced engine power and performance

- Difficulty starting the engine

Diagnosing and Resolving Fuel Filter Issues

To effectively troubleshoot and resolve fuel filter-related problems, follow these steps:

- Visually inspect the fuel filter for any signs of damage, such as cracks, leaks, or obstructions.

- Check the fuel filter’s pressure and flow rate to ensure they meet the manufacturer’s specifications.

- If the filter is clogged, replace it with a new one to restore optimal fuel flow and engine performance.

- Consider the fuel quality and any potential contaminants that may be causing the filter to clog prematurely.

- Ensure the fuel system is free of any leaks or other issues that could contribute to the problem.

Fuel Filter Maintenance Strategies

Proactive maintenance is key to preventing fuel filter-related issues and keeping your engine running at its best. Here are some expert-recommended maintenance strategies:

| Maintenance Task | Frequency |

|---|---|

| Fuel filter replacement | Every 12-24 months or as per manufacturer recommendations |

| Fuel system cleaning | Every 12-18 months or as needed |

| Fuel quality inspection | Regularly, especially when experiencing issues |

By following these fuel filter troubleshooting and maintenance strategies, engineering and technology professionals can ensure optimal engine performance, reduce downtime, and extend the lifespan of their equipment.

Post Comment